PRODUCTS

CATEGORY

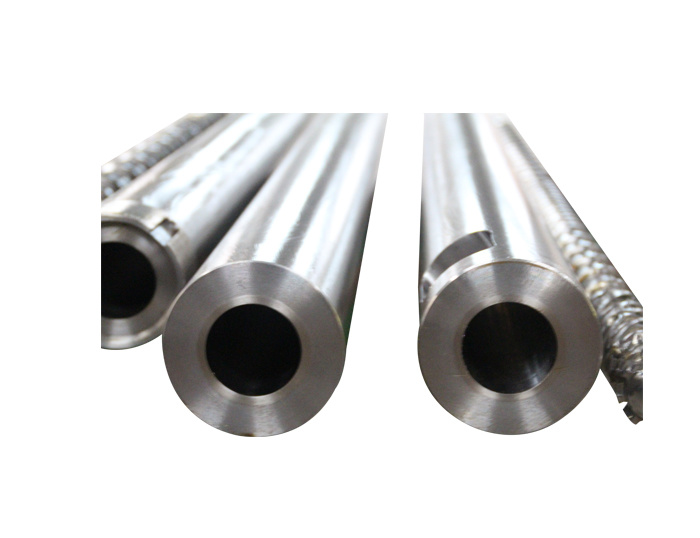

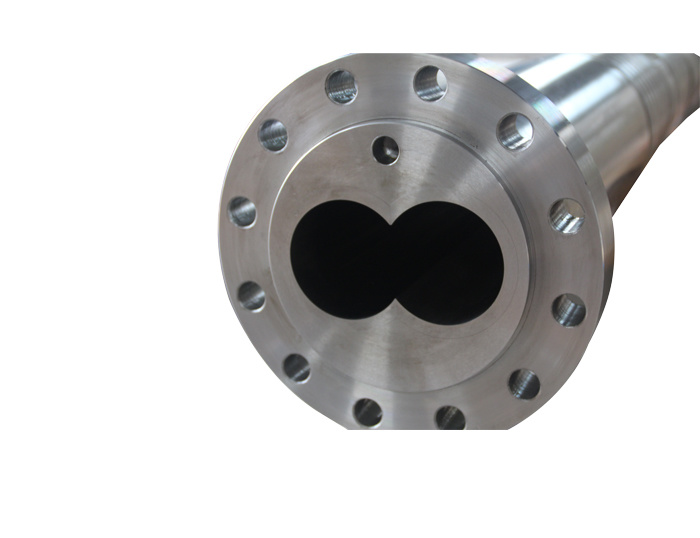

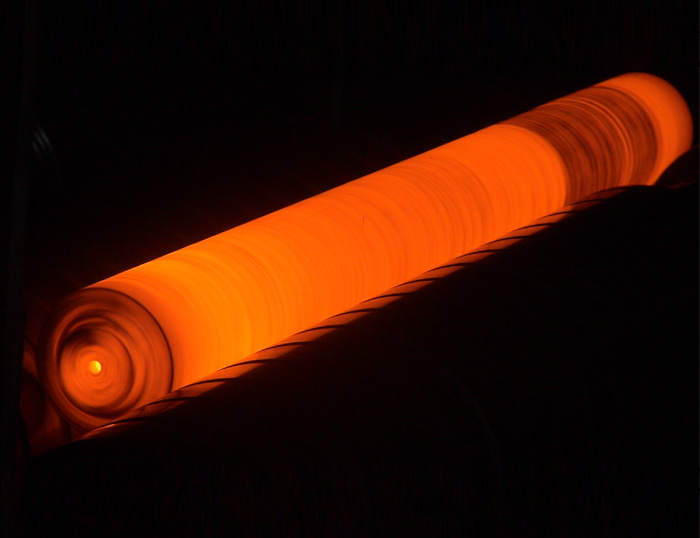

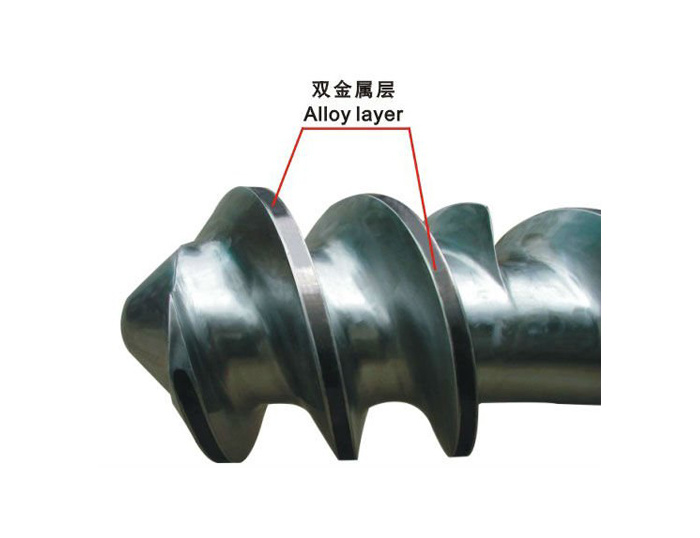

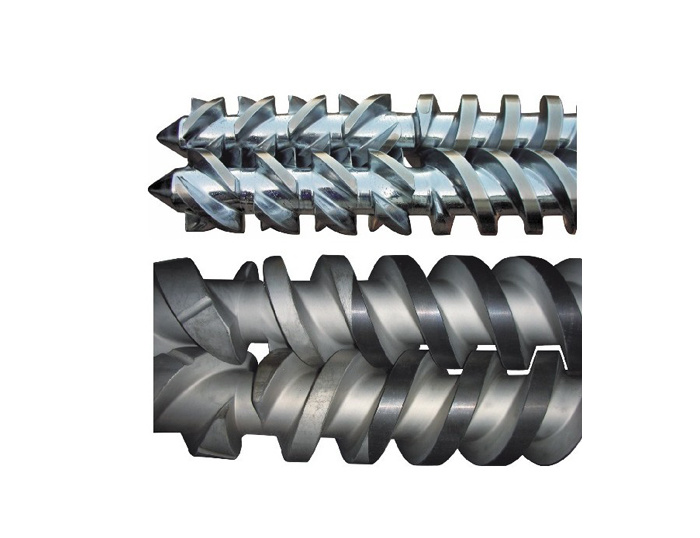

Wc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn MoreWc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn MoreWc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn MoreWc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn MoreWc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn MoreWc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn MoreWc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn MoreWc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn MoreWc-10 tungsten carbide alloy, with the characteristic of high hardness, high hard-wearing, corrosion resistance, and high-temperature resistance, the hardness of alloy layer reaches HRC60°-65°, thus having the service life of five or six times longer than the nitrided barrel. It is suitable for the processing of PC plus 30%-50% fiber glass, bakelite, dynamoelectric injection machine, magnetic particle, ceramic powder, aluminum and magnesium powder, ferrous powder, copper powder,etc.

Learn More